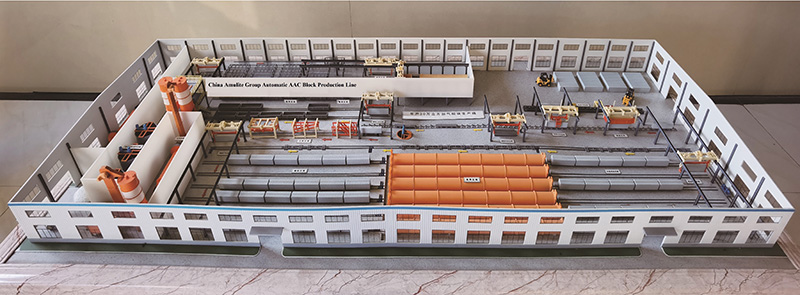

Amulite Automatic AAC Block Production Line

Tlhaloso e Khutšoanyane:

Lintlha tsa Sehlahisoa

Li-tag tsa Sehlahisoa

AAC Block ke Eng?

Khopolo ea AAC Block: AAC Block E Thehiloe holim'a Lisebelisoa tsa Siliceous(Lehlabathe, Fly Ash, Silica-Containing Materials jj), Le Calcareous Materials(Lime, Cement) E le The Main Raw Materials, e Kopantsoeng le Air-Entraining Agents(Aluminium Powder) ,Kamora The Process Raw Materials Batching,Slurry Mixing,Ho tšela,Pre-Curing,Cutting,Autoclave,Curing process le sephutheloana sa ho hlahisa lihlahisoa tse felileng tsa AAC Blocks; e bitsoa Aerated Concrete hobane e na le palo e kholo ea li-uniform le tse nyane ka mor'a E na le Moea.

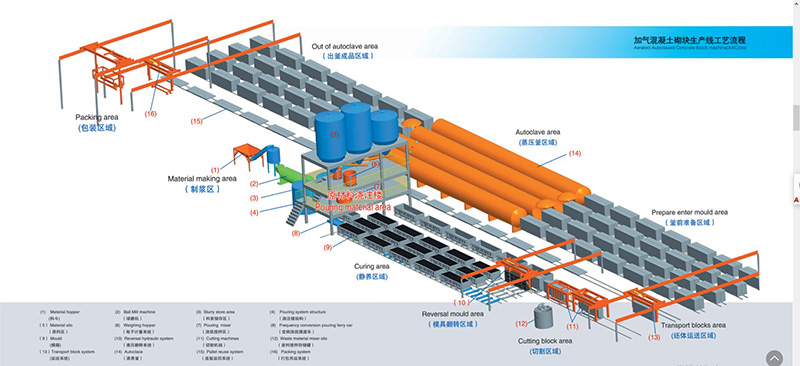

Mokhoa oa ho Hlahisa Lihlahisoa tsa AAC Block ke Efe?

Mokhoa oa ho Hlahisa Lihlahisoa tsa AAC Block ke Efe?

1) : All Raw Materials Metering And Mixed Slurry;

2) : Slurry Kena ka ho Tšela System, Ka mor'a Ho Kopanya Ebe U Tšela Ka Lebokose la Mold;

3) : Ka hare Mold Box(Panel Reinforcement),Ka mor'a A itseng Mocheso le Pele ho Phekola Nako;

4) : Kamora hore Panele e Metsi e Fihlelle Bothata bo itseng, Lebokose la Mold le liphanele li tla phahamisoa ho Mochini oa ho Seha ka Crane ea Turnover, 'me Crane ea Turnover e phethela tšebetso e latelang:

4

7 Ho tšela ;

6

8) :Qetellong Cuts Horizontal Horizontal Kapa Thipa Seha;

9) : The Cut Panel Body E Hoisted From Semi-Finished Product Crane Hammoho le The Bottom Plate Ho The Autoclave Trolley;

10) :E ntan'o hlophisoa ka Autoclave Bakeng sa Mocheso o Phahameng le Pheliso e Phahameng ea Khatello;

11) : Ka mor'a ho folisa Autoclave hantle, trolley e tla ntšoa 'me e tlohele Autoclave;

12) : The Finished Products Are stacked or loaded On The Truck By Finished Product Hosting Crane, Packaged Well;

13) : The Autoclave Curing Side Plate E Khutlisitsoe;

Mabapi le Selelekela sa Main Raw Materials

Tlhahiso ea AAC Block e Ruile ka Lisebelisoa tse tala, Haholo-holo Tšebeliso ea Fly Ash e le Lisebelisoa tse tala tse ke keng tsa sebelisa ka botlalo feela masala a litšila tsa indasteri, ho sebetsana le tšilafalo ea tikoloho, eseng ho senya masimo, empa hape ho theha melemo e metle ea sechaba le moruo, Is A Good Substitute For Traditional Solid Clay Bricks.Lihlahisoa tse Ntle tse Tšepisitsoeng tsa Lerako li Amohile ka Matla ke Mmuso, Khampani ea Matlo, Sehlopha sa Kaho, 'Me 'Muso o Entse Leano la Lekhetho, Tšehetso ea Leano la Tšireletso ea Tikoloho, Re ka Bona esale Pele Litebello Tse Pharalletseng tsa Tsoelo-pele ea Maraka;

1. Fly Ash / Quartz Sand

Lehlabathe la Fly Ash / Quartz Ke The Main Core Raw Materials Of AAC Block Product, 'me ke Mohloli o ka Sehloohong oa Silicon le Aluminium Components Of Aerated Concrete;

2. Samente

Samente ke Mohloli o ka Sehloohong oa Matla a AAC Block,E fana ka The Main Calcareous Materials For AAC Block, Cement Loketseng Bakeng sa Tlhahiso ea AAC Block Lokela ho Khetha Haholo-holo ka dipehelo tsa Mofuta le Kereiti ya Cement;Ka tlhahiso,52.5 Kereiti e Tloaelehileng Portland. Samente e Lokela ho Khetha Pele .Ka Kakaretso, E le Ho Fokotsa Litšenyehelo tsa Tlhahiso, 42.5 Sehlopha se Tloaelehileng sa Samente sa Portland se ka Sebelisa Hape;

3. Kalaka

Lime Hape ke E 'ngoe ea Lintho Tse Ka sehloohong tse Raw Bakeng sa Tlhahiso ea AAC Blocks.Mosebetsi oa eona o ka Sehloohong ke Ho sebelisana le Samente ho Fana ka Katleho ea Calcium Oxide, e le Hore e Kopane le SIO2 le Al203 ka Lisebelisoa tsa Siliceous Tlas'a Maemo a Hydrothermal Ho Hlahisa Silicon Hydrate Calcium. Acid.Ka lebaka leo, Lime ke E 'ngoe ea Mehloli e Meholo ea Matla ea AAC Block.The Katleho Calcium Oxide Content Of Lime E Sebediswang Ho Hlahisa AAC Block E Lokelang ho ba Holimo ho Feta 65%,Haholo-holo e Phahameng ho Feta 80%.

4. Gypsum

Gypsum Ke Regulator Of The Air Evolution Process In AAC Block Production.The Regulating Effect of Gypsum is Haholo-holo e Bonahatsoang ka Ho lieha ha Quicklime Digestion le Slurry Thickening Speed.The Main Chemical Component Of Gypsum Is CASO4;Ho na le Mefuta e meraro ea Gypsum ka The 'Maraka;Gypsum e tala,Anhydrite le Plaster ea Paris.Ho ekelletsa moo, Gypsum ea litšila e boetse e hlahisoa molemong oa tlhahiso ea lik'hemik'hale.joalo ka Phosphogypsum e tsoang ho tlhahiso ea menontsha ea phosphate,fluorogypsum e tsoang ho tlhahiso ea lik'hemik'hale tsa fluorine, le gypsum e tsoang tlhahiso ea titanium. Dioxide.Tsena Gypsum li na le litšenyehelo tse tlase 'me li ka nka sebaka sa Gypsum ea tlhaho le ho fokotsa litšenyehelo tsa tlhahiso;

5. Moemeli ea Hlahisang Moea

AAC Block Lokela ho ba le Air-Generating Agent Ho Bōpa Pores In The Block Ho Etsa A Bonolo Porous Structure;

6. Foam Stabilizer

Ka mor'a Khase ea Moemeli ea Hlahisang Moea, ka lebaka la Lerako le Lesesaane la Foromo, ho bonolo ho senya le ho senya Foam tlas'a tšitiso ea maemo a fapaneng, e amang boleng ba konkreite. Ka hona, hoa hlokahala ho kenya Foam Stabilizer ho Slurry.

Mokhoa oa Tlhahiso

1) :Storage And Supply Of Raw Materials For AAC Block

Lisebelisuoa tse tala li Isoa Fekthering ka Likoloi, 'me Fly(Lehlabathe,Powder ea Lejoe) e Kentsoe Jarete ea Raw Materials,'me ha e sebelisoa, e fetisetsoa ka har'a Hopper. Samente e behiloeng kapa samente e ngata e bolokoa ka polokelong ea samente. Ha e sebelisoa, E Laeloa 'me e Isoa ka Hopper.Chemicals,Aluminium Powder Etc E Behiloe Ka Sebolokelong sa Lik'hemik'hale le Powder ea Aluminium, ka ho latellana,'me e Fetisetsoa Setsing sa Ts'ebetso ha se sebelisoa.

2) ![]() rocessing Of Raw Materials Bakeng sa AAC Blocks

rocessing Of Raw Materials Bakeng sa AAC Blocks

Fly Ash(Kapa Lehlabathe, Powder ea Lejoe) E Romeloa Ball Mill ka Electromagnetic Vibrating Feeder le Belt Conveyor, 'me The Ground Fly Ash(Kapa Lehlabathe,Powder ea Lejoe) e Romeloa Tankeng ea Slurry Bakeng sa ho Boloka Ke Fly Ash Pump.

Lime li Romeloa ho Jaw Crusher ke Electromagnetic Vibrating Feeder Le Belt Conveyor Bakeng sa ho Silakanya. The Lime Crushed E Felisoa Tankeng ea polokelo ea lime ka Bucket Elevator, 'Me e Isoa The Ball Mill ke Screw Conveyor.The Screw Conveyor And Bucket Elevator E Fepeloa ka Tankang ea Powder Batching. Ka mor'a hore Lik'hemik'hale li lekanyetsoe ka Botsona ka Karolo e itseng, Tharollo ea Maemo a Mang a Etsoa 'me a Romeloa Tankeng ea Polokelo Bakeng sa Polokelo.

Phofo ea Aluminium e Felisoa ho Tloha Setorong sa Phofo ea Aluminium ho ea Setsing sa Tlhahiso, 'me e phahamisetsoa Mokatong oa Bobeli oa Moaho oa ho Batching o nang le Motlakase oa Motlakase. Tšela ka Motsoakong ho Eketsa Metsi ka Bongata, 'me U o Susumelle ka Ponong ea Aluminium Powder.

3) : Ho Kopanya Slurry, Le ho Tšela Of AAC Blocks;

Kalaka le Samente li Romeloa ka Tatelano Sekala sa Boima ba Boima bo Ikemetseng ka Sekoahelo sa Screw Tlas'a Tanka ea Powder Batching Bakeng sa Measurement ea Cumulative.Ho na le Conveyor ea Screw Tlas'a Sekala ho Eketsa Thepa ka ho Kopanya Ka har'a Motsoako o Tšelang.

Fofa Molora(Kapa Lehlabathe, Phofo ea Lejoe) le Litšila tsa Slurry li kentsoe ka har'a moqomo oa ho lekanya. Kamora hore lisebelisoa tse fapaneng li lekanyetsoe, hlobo e se e le teng, 'me seretse se ka tsosoa. ℃) Pele o Tšela.Haeba Mocheso o sa Lekane, ho futhumatsa ha Autoclave ho ka etsoa ka tanka ea slurry metering, 'me ho emisoa ha phofo ea aluminium ho ka eketsoa 0.5-1 Minute pele lisebelisoa li tšeloa;

4): AAC Block Pre-Curing And Cutting

Ka mor'a ho tšela, Lebokose la Mold le sutumelloa ka kamoreng ea pele ea ho folisa ka ketane ea conveyor bakeng sa gasification le boemo ba pele. Mocheso oa kamore ke 50 ~ 70 ℃, 'me nako ea pele ea ho folisa ke 1.5-2Hours (ho ea ka maemo a monate a sebaka, Tshebetso e ka Felisoa).Sebelisa Mohatla o Mobe ho Phahamisa Mould Frame le 'Mele oa Thibelo o Metsi Holim'a Tafole ea ho Seha Moo ho Behiloe Plate e ka Tlase ea Autoclave Trolley Esale Pele.Tlosa Mold Frame.The Cutting Machine Cross-Cuts ,Longitudinally Cuts,And Mills The Wet Block.Mould Frame e Hoamisoa Morao ho Lori ea Mold bakeng sa ho hloeka le ho hloekisoa, ebe e phahamisetsoa ka har'a teraka ea mold bakeng sa ho lahla se latelang. 'Mele oa Cut Block le Plate e ka Tlase ea Autoclave li phahamiselitsoe ho Autoclave Trolley e nang le Crane ebe e behoa holim'a. Mekato e 'Meli.Ho na le Litšehetso tse' Nne Pakeng tsa Mekato, 'me Likoloi tse 'maloa tsa Autoclave li kopantsoe hammoho.

Lisebelisuoa tse Mathōkong le Likhutlong Tsa 'mele o Metsi o Hlahisoang Nakong ea ho Seha o Isoa Setsing sa Litšila tsa Slurry Haufi le Mochini oa ho Seha ka Screw Conveyor,' me Metsi a Eketsoa ho Etsa Seretse se Senyehileng Bakeng sa Tšebeliso ea Batching.

5) :Autoclaved AAC Block And Finished Product.

Ka mor'a hore 'mele o bokelloe Moleng oa ho Paka ka pel'a Autoclave,Bula Monyako oa Autoclave o Tsoang Ka har'a Autoclave,Pele u hule trolley e felileng ea Autoclave ka har'a Autoclave e nang le Hoist,'me U hule trolley ea Autoclave hore e be Autoclave. Ka har'a Autoclave e nang le Hoist The Autoclave E bolokiloe.The Finished Products On Autoclave Trolley E Hoisted To Finished Product Warehouse By A Bridge Crane,Ebe E Isoa The Finished Products Yard Ke Forklift Truck.The Empty Autoclave Trolley And The Bottom Letlapa la Autoclave Running le phahamisitsoe ho khutlela moleng oa ho khutlisa koloi, 'me stacker e huleloa ka morao ka mor'a ho hloekisa.E-ea ho Lebelo le Latelang.

Pontšo ea Lisebelisoa tsa Tlhahiso

1): Ho sila lintho tse bonahalang le ho etsa Karolo ea Slurry

| The Traditional Process Of Slurry Density Control is not Strict .The Density Of Protoplasm is often through Artificial Measurement .Phoso E kholoanyane .Sekhahla se Tšoanelehang le Boleng ba Sehlahisoa ha se Se Loketseng1.The Slurry E Potolohile Pakeng Tsa Tanka Le Densimeter, The Slurry Density Data E Lekanyetsoa Ka Density Pipeline In Real Lime Le Maikutlo ho Phaposi e Bohareng ea Taolo .E le Hore ho Fetole Karohano ea Metsi ea Pulping ea Ball Mill le Ho Tlatsa. Of The Slurry Tank .Morero oa ho Tsoela Pele ho Lokisa Tšebeliso ea Nako ea Sebele e Fihliloe:2.The Density Pipe E Tla Lekanya Tekanyo ea Tsohle Tse Slurry .Lekanya ho Nepaha Ntle le Phoso.'Me Joale Hlahla Pipe E Feletseng Ka mor'a Shift ho Etsa bonnete ba ho nepahala ha Tekanyo e Latelang. |  | |||

| ||||

| Mochini oa ho Etsa Molora oa Seretse se Fofang | Slurry Storage Mixer | Material Scale | Sistimi ea ho tšela | |

| 2):Turnover le Karolo ea ho Seha | ||||

Lintlha Tse ka Sehloohong Tsa Mochini oa ho Seha Amulite1) : E bonolo-e hlophisitsoeng, e bonolo ho kenya le ho e boloka;2) : E tsitsitse ho ea fatše, e khannoang ke Planet-Gear Reducer, ha e ntse e etsa ho itšeha ka ho toba, Mochini oa ho Seha o Etsa Eccentric le Swinging Cutting e Eketsang ho Seha Ka katleho.E Etsa Hore ho be bonolo haholoanyane ho fetola boholo ba ho itšeha. Lintlha Tse ka Sehloohong Tsa Mochini oa ho Seha Amulite1) : E bonolo-e hlophisitsoeng, e bonolo ho kenya le ho e boloka;2) : E tsitsitse ho ea fatše, e khannoang ke Planet-Gear Reducer, ha e ntse e etsa ho itšeha ka ho toba, Mochini oa ho Seha o Etsa Eccentric le Swinging Cutting e Eketsang ho Seha Ka katleho.E Etsa Hore ho be bonolo haholoanyane ho fetola boholo ba ho itšeha. 4 2 5) :High Roughness Of The Surface Of Finished Blocks Ke Favorable For Building Operation And Construction. 7 | ||||

| ||||

| Hydraulic Frequency Convert Turnover Crane | Mochini oa ho Seha o otlolohileng | |||

| 1) :Hydraulic Frequency Fetola Turnover Crane Fetola The Mold Box With Block In 90 Degree Turnover,E behe On The Frequency Convert Block Dragging Trolley And Process Demold Works;1 | Turnover Crane e Fetolela Mold 90 Degree, Demold 'me e Behe Block Eohle le Plate e ka Tlase holim'a Trolley Lintho Tse Senyehileng. | |||

| ||||

| 3): Turnover Crane Ho Tlosa The Bottom Waste Material | ||||||||||

| Sesebelisoa sena se Iketselitse ke Sehlopha sa Amulite ho Thusa Bareki ba Rona ho Rarolla ka ho Felletseng Bothata ba Letlapa la Lintho Tse Tlase.Sesebelisoa sena se kenyelletsa Turnover Platform le Crane, se ka tlosa litšila tse kaholimo le tse tlase. Crane ena e ka ba joalo ka Semi-Product Transport Crane. | |||||||||

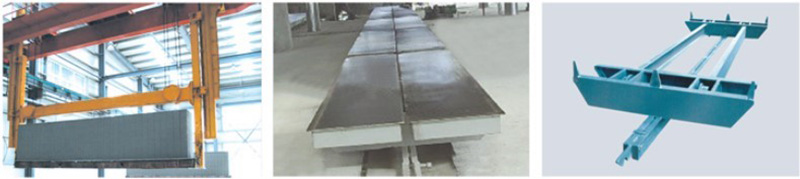

| Transport Crane Pele ho Autoclave | Plate ea Motheo | Autoclave Trolley | ||||||||

| ||||||||||

| Ka mor'a ho Seha, Transport Crane Carry Block To Autoclave Trolley Bakeng sa Kena Autoclave.Sesebelisoa sena se na le Sebopeho se Bonolo, Ts'ebetso e tsitsitseng, Boleng bo Botle 'me ho Bonolo ho E Boloka. | Plate ea Base E entsoe ke Sehlopha sa Amulite le eona e ka ba Plate ea Mahlakoreng, ha ho hlokahale hore e fetohe ho fihlela e tsoa ho Autoclave. | E entsoe ka tšepe e ntle ea boleng bo botle 'me e na le Sebopeho se Bonolo Conserved Ho fihlela Tlosa The Finished Blocks; | ||||||||

| 4): E felile Sehlahisoa sa ho sebetsana le thepa | ||||||||||

| Hangata The Autoclaved Blocks 'me Plates tla ba le adhesions Ka linako tse ling.The Seperating Machine ke ho Fella Arohane The Adhesion ea Blocks Ntle le Tšenyo Leha e le efe ho The Blocks,E leng Kopanya Mosebetsi oa Setso Arohanyang Machine Le The Finished Product Carrier.Letsoho le leng le le leng le arohaneng le laoloa ka boikemelo, E rarolle bothata ba ho arola li-blocks le liphanele ka har'a hlobo e ts'oanang; Thepa e Lemoha Ts'ebetso e Ntle le e Bonolo, e theola litšenyehelo le ho netefatsa sekhahla sa boleng ka nako e ts'oanang. | |||||||||

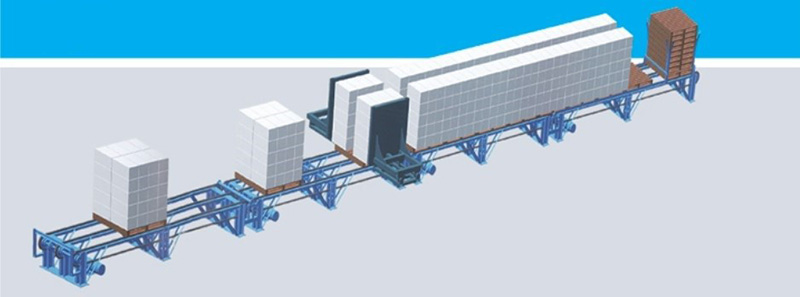

| Convey And Package Line | ||||||||||

| ||||||||||

| Mohala ona oa Sisteme o kenyelletsa Mohala oa ho tsamaisa le ho paka bakeng sa lipallet tsa lehong tse etselitsoeng haholo li-block tsa AAC tse felisitsoeng. The Whole Mold Products e tla fetisetsoa holim'a pallet ea lehong ka nako e le 'ngoe ka mokhoa oa ho koala sesebelisoa bakeng sa lihlahisoa tse felileng bakeng sa ho fetisa ho tsamaisa le ho paka. Mohala ona.Mochini ona o na le Litšobotsi tse joalo ka Phatlalatso e Ikemetseng ka Taolo ea Khomphutha, Positioning e nepahetseng Nakong ea Convey le Karohano e Ikemetseng ea Pallet ea Lehong e Ileng ea Laela Moo ho leng bonolo ho Paka le ho Romela. | ||||||||||

| 5): Mechine e meng e bonts'a | ||||||||||

Sehlahisoa se Felletseng Clamp Sehlahisoa se Felletseng Clamp |  Rotary Clamp Rotary Clamp | |||||||||

| ||||||||||

| Crane e khethehileng bakeng sa liphanele | Mochini oa plug | Open Slot Machine | ||||||||

| ||||||||||

| Ball Mill | Mohlahare oa Mohlahare | Autoclave | Boiler | |||||||

| ||||||||||