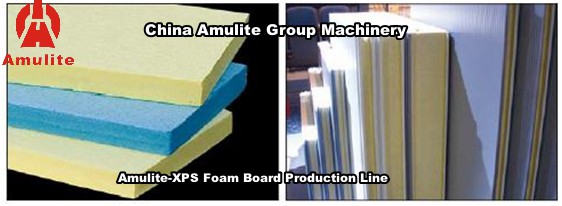

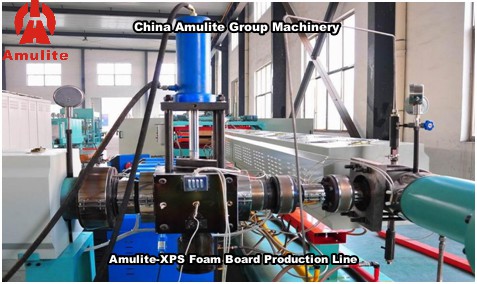

Amulite CO2 XPS Foam Board Production Line

Tlhaloso e Khutšoanyane:

I. Selelekela sa Technical

Taba ea pele, ho kopanya thepa ea XPS ea symmetrical1y le lisebelisoa tse ling tsa mothusi tse kang nucleant le batch ea mebala; La bobeli li kenye ka har'a hopper ea Kereiti ea Iextruder ka vacuum feeder automatical1y; Resin ea boraro e qhibilihang le ho etsa polasetiki ka ho khetheha, ka nako e ts'oanang o kenya sekontiri sa foam ka khatello e phahameng. E na le resin e qhibilihisitsoeng; ea bone, ho li kenya ka har'a Grade IIextrusion system ho kopana, ho kopanya, ho eketsa khatello le ho pholile hape le ho ntša foam board ka hlobo e khethehileng bakeng sa boto, ebe o pholile le ho etsa boto ka ho pholile le ho etsa dexiss..kifthly.ho kenya boto tsamaisong ea ho hula ea Mophato oa Pele le ho tsamaisa theminto tsamaisong ea ho hula ea Mophato oa Pele ka lipalangoang;Ntlha ea botšelela, ho khaola litšila ka mahlakoreng a mabeli le ho qeta ho itšeha ho ea ka sete sa 1;mohato oa pele, ho bokella le ho boloka.

Lintlha tsa Sehlahisoa

Li-tag tsa Sehlahisoa

Setsi sa Motlakase:

Enjene e kholo ea Beide Brand (Siemens Standard Motors Ltd.)

Transducer Danfoss kapa Siemens Brand

AC Contactor Siemens kapa Schneider Brand Mocheso taolo mitha Omron Brand kapa Fuji Brand Voltage 380V,50HZ

AM-XPS75P/200 CO2XPS Foam Board Production Line

I.Theknolojial Selelekela

Taba ea pele, ho kopanya thepa ea XPS ka symmetrically ka lisebelisoa tse ling tse thusang joalo ka nucleant le batch ea mebala;Ea bobeli li kenye ka har'a hopper ea Kereiti ea I extruder ka vacuum feeder ka bo eona;Resin ea boraro ea ho qhibiliha le ho etsa polasetiki ka sekoti se entsoeng ka mokhoa o ikhethileng, ka nako e ts'oanang o kenya mochini oa foam ka khatello e phahameng ebe o o kopanya le resin e qhibilihisitsoeng;Ntlha ea bone, ho li kenya ka har'a tsamaiso ea Grade II ea extrusion ho qhibiliha, ho kopanya, ho eketsa khatello le ho pholile hape le ho ntša foam board ka hlobo e khethehileng bakeng sa boto, ebe o pholile le ho etsa boto ka ho pholile le ho etsa sesebelisoa; ho tlosa tsamaiso le ho li tsamaisa

ho kena tsamaisong ea ho hula ea Mophato oa II ka lipalangoang;Ntlha ea botšelela, ho khaola litšila ka

sakha ea mahlakoreng a mabeli le ho qeta ho itšeha ho pota-pota ho latela bolelele bo behiloeng;mohato oa ho qetela, stacking le polokelo.

II.The Main Lintho tse bonahalang

1> XPS resin

2> Foam agent & thusa foam agent 3> Nucleant agent

4> Sehlopha sa mebala

5> Lisebelisoa tse ling tsa mothusi

Tlhokomeliso: Re tla fa bareki ba rona lengolo la ngaka, mofuta oa thepa le litokomane tse amanang le tekheniki kamora ho saena konteraka.

Karolo ea Mochini

1> Motsoako oa polasetiki 1 sete

2> Grade I extrusion system 1 set

3> CO2Sistimi ea ente ea mochini oa foam 1 sete 4> Sistimi ea ente ea foam ea mothusi 1 set 5> CO2tsamaiso ea pontšo ea phallo 1 set 6> HCFC Foam ente ea agent 1 set 7> Automatic net-exchange system 1 set

8> Sehlopha sa II tsamaiso ea extrusion 1 sete

9> Extrusion die head 1 set

10> Mokhoa oa ho lekanya le oa ho hula 1 sete

11> Sistimi ea phetiso le pholiso 1 sete

12> Grade II draw-off system 1 set

13> Lengthways cutting system 1 set

14> Horizontal itšeha tsamaiso 1 sete

AM-75P/200 CO2XPS Foamed Board Production Line

1.Ho fepa tsamaiso

2.AM75/44Sekoere-mafahla extruder 1 beha

3.CO2Sistimi ea ente ea foam1 beha

4.Mothusi oa foam agent ente tsamaiso 1 sete

5.Sistimi ea ente ea mochini oa Freon Foam 1 beha

6.CO2phalla bontsha tsamaiso 1 sete

7.Ka ho iketsa net-phapanyetsano tsamaiso 1 sete

8.Sehlopha sa II extrusion tsamaiso 1 beha

9.Extrusion shoa hlooho 1 sete

10.Sistimi ea ho lekanya le ho hula 1 beha

11.Sistimi ea phetiso le pholiso 1 beha

12.Sehlopha sa II ho hulanya tsamaiso 1 sete

13.Bolelele ho poma tsamaiso 1 sete

14.E tshekaletseng ho poma tsamaiso 1 sete

15> Phapang ho poma tsamaiso 1 sete

15.Setsi sa motlakase

XPS Foamed Board Recycling and Pelletizer Machine

Mohlala AM-XPS-JR100B

1> Boto ea foam ea XPS moqhobi sesebelisoa 1 sete

2> Single screw plasticizing le extrusion sesebelisoa 1 sete

3> Sefe ho fetola letlooa sesebelisoa 1 beha

4> Ho phodisa tanka 1 sete

5> Ho khaola pellet mochini 1 sete

Tlhokomeliso: Karolo e kaholimo ea moemeli oa foam ke ea referense ea hau feela, data ea 'nete e lokisoa ho latela tlhoko ea thepa e tala le mmaraka.