Embossed Metal Composite Exterior Panels Production Line

Tlhaloso e Khutšoanyane:

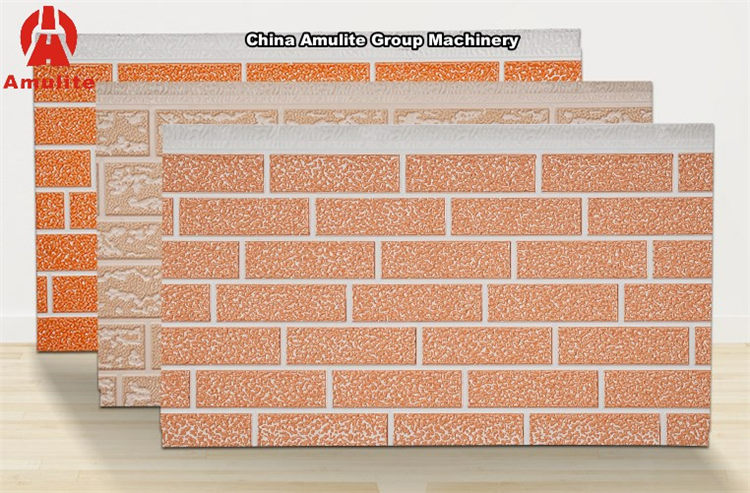

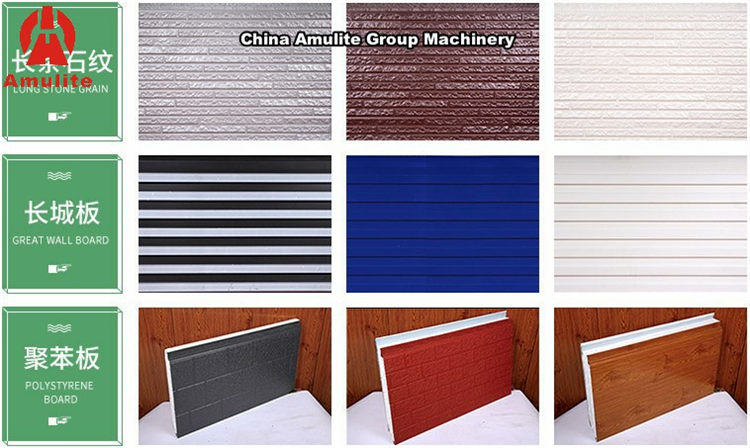

Embossed Metal Composite Exterior Panels Production Line ke tlhahiso ea thepa ea kaho e bobebe e bobebe ea mofuta o mocha eo hajoale e tsebahalang lefatšeng ka bophara.le likarolo tse khabisitsoeng tsa marako tse thehiloeng holim'a foam ea polyurethane.E ka hlahisa liphanele tsa mabota tse khabisoang tse thibelang mollo tse nang le poleiti ea tšepe holim'a metsi.polyurethane bohareng.le foil ea aluminium kapa poleiti ea tšepe ka tlase.

Lintlha tsa Sehlahisoa

Li-tag tsa Sehlahisoa

1. Selelekela sa Panel ea Lerako

Embossed Metal Composite Exterior Panels Production Line ke tlhahiso ea thepa ea kaho e bobebe e bobebe ea mofuta o mocha eo hajoale e tsebahalang lefatšeng ka bophara.le likarolo tse khabisitsoeng tsa marako tse thehiloeng holim'a foam ea polyurethane.E ka hlahisa liphanele tsa mabota tse khabisoang tse thibelang mollo tse nang le poleiti ea tšepe holim'a metsi.polyurethane bohareng.le aluminium foil kapa poleiti ea tšepe ka tlase.Libaka tse kholo tsa ts'ebeliso ea lihlahisoa: nchafatso ea meaho ea khale.lifolete tsa villa tsa maemo a holimo.villas.lihotele.meaho ea tšepe e bobebe.matlo a tsamaeang.matlo a mapolasi.litsi tse kholo tsa mabenkele.mabota a ka hare le kantle a lifeme.etc.

2. Sebopeho sa Thepa

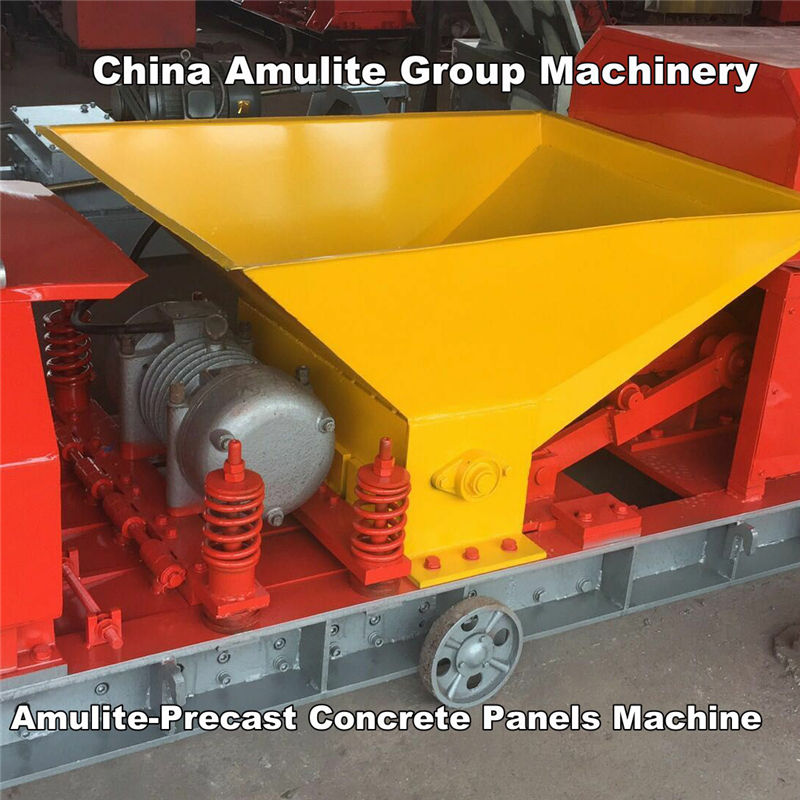

Embossed Metal Composite Exterior Panels Production Main Unwinder→ Embossing Machine→ Leveling Machine→ Side Forming Machine→ Heating Platform→ AB Foam Machine Enjection→ Aluminium Chain Plate Laminating Machine→ Saw Board Cut Off→ Coloring→ Packing Etc.

3. Embossed Metal Composite Exterior Panels Production Line Main Technical Parameters

Tlhaloso ea Panel ea Lebota: A.380 × 16 limilimithara B. (380-500) × (30-40) limilimithara

Lebelo la Tlhahiso: 4-10m / min

Bolelele ba Aluminium Alloy Double Crawler: 18-24m

Kakaretso ea Matla a Thepa: Hoo e ka bang 60Kw

Bokhoni ba Mohala oa Tlhahiso: Hoo e ka bang 1. 000. 000Sq.m.

4. Embossed Metal Composite Exterior Panels Production Line Kenyelletso ea Sebopeho sa Yuniti le Mosebetsi

Ⅰ.Unwinder

Mosebetsi: E Sebelisitsoe Bakeng sa ho phutholoha le ho Embossing ea Likhoeli tsa tšepe

Mofuta oa Sebopeho: Karolo ea tšepe ea Welding Frame.Phallo ea Ka morao e Lemoha ka Hydraulic Cylinder.Thibela ho kheloha ha Coil Material.Unwinding Adpts Passive Type.E-ba le Pneumatic Brake Bakeng sa Taolo ea Tension.

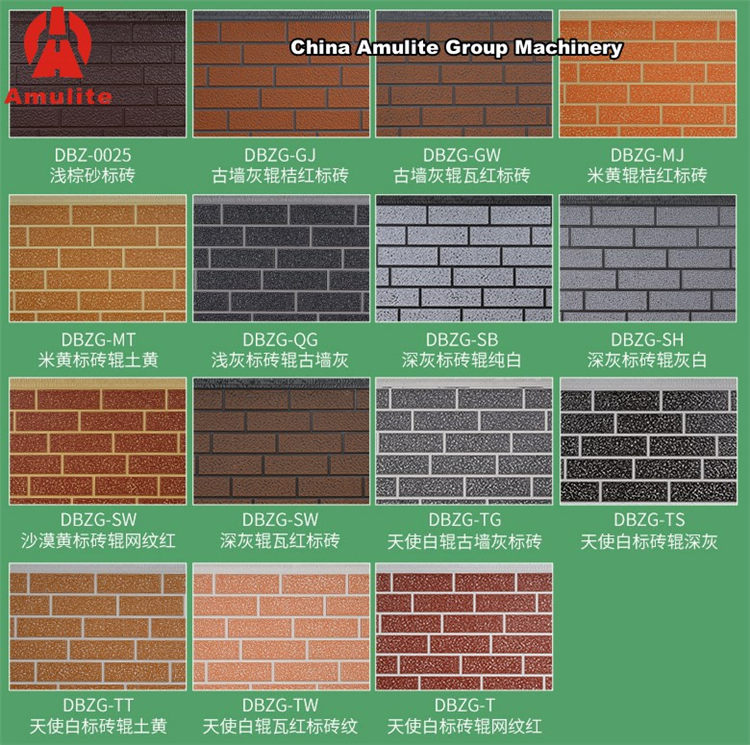

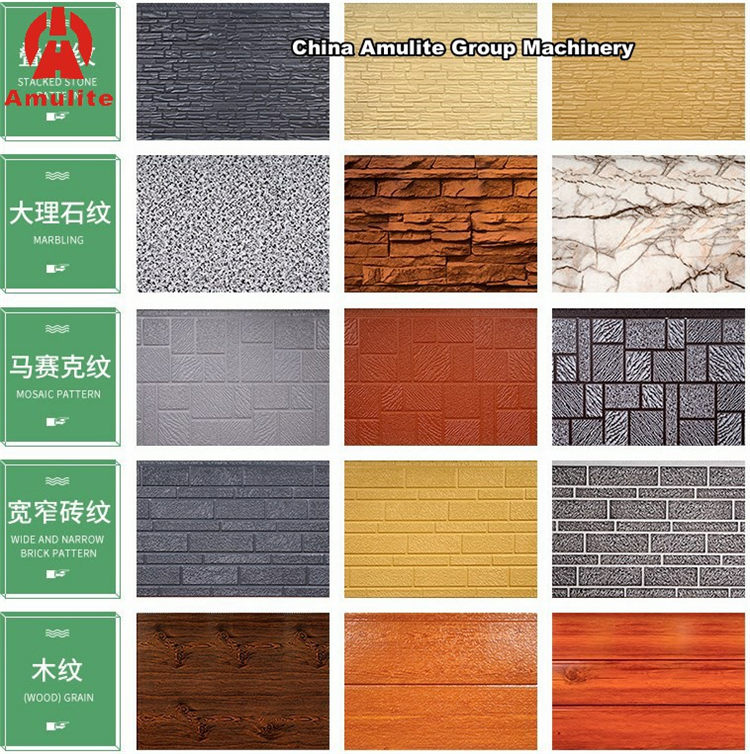

Ⅱ.Mochini oa ho Embossing

Mosebetsi: Ho ea ka mekhoa e fapaneng ea Wall Panel.Lirolara tse peli tse hanyetsanang tsa Embossing li sebelisoa ho hatisa mekhoa e fapaneng ea tšepe ea mebala.

Ⅲ.Mochini oa ho Foaming:

BLC(R) Mofuta o Motlakase oa Mochini o Tsoelang Pele o Foamisang Lefuba Kapa PH(R/F) Mochini o Foaming oa Khatello e Phahameng.Sebelisa 1 Resin (A) Tanka.Tanka ea 1 ea Phekolo ea Moemeli (B); Likarolo tse peli tsa Pompo ea Methara li tsamaisoa ke Li-motor tse Ikemetseng tsa Frequency.Phallo ea Phallo ea Pompe ea Metering e Laoloa ka ho Fetola Lebelo la Pompe ea Metara.Qetellong.Likarolo li tsoakoa ho latela karo-karolelano e hlokehang 'me li fafatsoa ka ho lekana lipakeng tsa lipoleiti tsa tšepe tse tlase kapa li-substrates tse ling.

Ⅳ.Mochini oa ho etsa

Mosebetsi: Sebopeho sa tšepe e kentsoeng ea 'mala se ne se phekoloa ke Multi Wheel Flanging.

Ⅴ.Laminator

Mosebetsi: E Felletse ka Foaming Marang-rang le Sebopeho sa Polyurethane; Yuniti ea Plate ea Chain e entsoe ka Drive Motor.Lebili la Ketane.Aluminium Alloy Chain Plate.Pin Shaft And Rolling Bearing.Ho Sebelisa Mokhoa oa ho futhumatsa Tube ea Motlakase; E ka Chesa ka Potlako Mochini oa Belt habeli ho Mocheso o Hlokehang Bakeng sa Tlhahiso.Motlakase o futhumatsang o ka buloa kapa oa tima ho latela maemo a teng.

Ⅵ.Mochini oa Sawing oa Bolelele o tsitsitseng

Mosebetsi: O bone Boto e Thehiloeng ho ea ka boholo bo behiloeng.

mosebetsi: The Base.Fuselage le Upper Movable Frame Adopt Karolo ea tšepe le Plate Welding Sebopeho.E hokahane le Linear Guide Rail.Sebaka se Mountang sa Terene ea Tataiso se Felisitsoe.Netefatsa ho Hlokahala ho Nepahetse; Motlakase oa Sawing o kentsoe Foreimi e ka Holimo ea Moving.Foreimi e Tsamaeang e Tsamauoa ke Enjene e Geared.Lateral Movement; Sesebelisoa sa Clamping se kentsoe 'Meleng.E entsoe ka Air Cylinder le Pressing Block;Sesebelisoa sa Reset se entsoe ka Cylinder le Sesebelisoa sa Buffer; Ha Plate e fihla Bolelele bo Behiloeng.The Clamping Cylinder e Sutumelletsa Thibelo Ho Tlase.Le Reset Cylinder Sutumetsa 'Mele Ho Tsamaea le Plate;Ka nako e tšoanang.Motlakase oa Sawing o Qala.'Me Motlakase oa Phokotso o Tsamaisa Frame ea Ho Tsamaea ka Holimo Ho Tsamaea ka Ho Holimo.Kahoo Joalo ka Ho Hlokomela Transverse seha Of Plate;Ka mor'a hore ho khaola ho phethoe.Sesebelisoa sa Clamping se Phahamisitsoe.'Me Cylinder ea Reset e Khanna' mele ho Khutlela Ntlheng ea Pele ho Reset.

5. Embossed Metal Composite Exterior Panels Production Line Automatic Control

The Automatic Control System E arotsoe ka Likarolo tse 'nè: Ho phutholoha le ho Embossing Sebaka sa Taolo.Ho theha le ho Lamination Area Control.Foaming Area Control And Sawing Area Control.Kakaretso ea Matla e ka ba 60KW; Sethala sa ho futhumatsa se ka ba 30KW.Sistimi e Felletseng ea Taolo e na le Molaoli ea ka Rarolloang.Teko Switch.Delta Inverter Driver le Likarolo tse ling.Ka The Touch Screen Parameter Input le Button Cooperation Operation.Hlokomela The Automated Production Of The Production Line.Ts'ebetso ea eona e ea Tšepahala 'me e tsitsitse.'Me ts'ebetso e bonolo ebile e bonolo.